Ikhoyili yocingo lwe-aluminiyam titanium boron AlTi3B1 AlTi5B0.2 aluminiyam master ialloy AlTiB yokuphosa isityalo

Isicelo:

I-Aluminiyam i-titanium boron yokucoca iinkozo isetyenziswa ngokubanzi kwi-aluminium casting, iprofayili ye-aluminium, intambo ye-aluminium, i-aluminium foil, i-aluminium strip kunye namanye amashishini.

Isantya sokongeza sibalwa ngokuhambelana nomxholo we-titanium we-alloy eveliswayo, kwaye yongezwa ngokulinganayo ukusuka kwi-flow trough nge-motor traction okanye manual.

Ingcaciso yeMveliso:

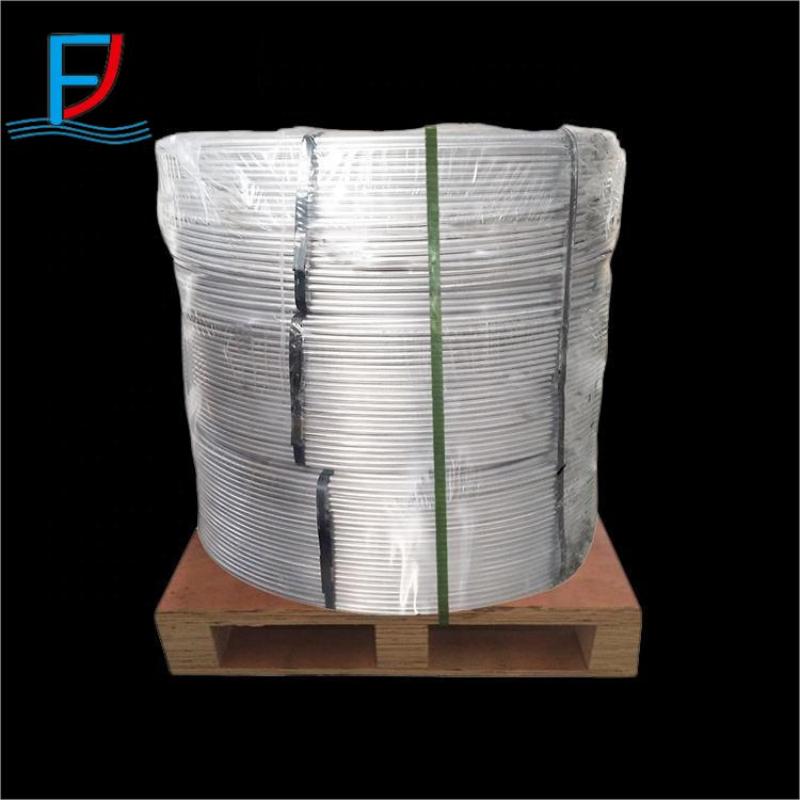

I-1.Le mveliso iqengqeleke ngezixhobo eziphambili kwidayamitha yesilika ye-Ø9.5mm kunye nenxeba kwimiqulu, imbonakalo yesilivere eqaqambileyo, ecocekileyo, i-bundles ejikelezayo ecwangciswe kakuhle.

2.Xa ujija intonga ye-aluminium ephosiweyo, yongezwa kwi-flow trough ukunciphisa ukutshisa okubangelwa ukungena kwisithando somlilo.

3.I-Titanium kunye ne-boron zisasazwa ngokulinganayo kwaye zisetyenziswa kancinci.

I-advanteji:

1.Ngokucacileyo phucula ubume bangaphakathi bentonga ye-aluminium.

I-2.Inokuphucula kakhulu iimpawu zokugqibela zomatshini weemveliso.

3.Ukunciphisa kunye noxinzelelo, ukunciphisa ukusetyenziswa kwamandla kunye nokufa kokulahlekelwa.

4.Phucula isantya se-extrusion kunye nokusebenza kakuhle kwemveliso.

5.Ukunyusa izinga lemveliso.

6.Phucula ukufana kunye nokuqaqamba kombala we-oxidation.

Uphawu:

1. Umxholo: Ti (4.5 -- 5.5%), B (0.8 -- 1.2%), Al: isibonelelo.

2.Ubukhulu begama Ø9.5mm, ukutenxa 0.5mm.

3.Bundle ubukhulu bangaphakathi 360 ± 25mm, 750 ± 25mm

4.Bundle ubunzima 170 ± 20kg

5.Ubude bendlela yokubala: Ubude (m) = ubunzima benqwaba (kg) ÷ 0.192 (kg/m)

6.Ukwandiswa kocingo: δ50 ≥ 12%

1.Q: Ziziphi iimveliso zakho eziphambili? A: Iimveliso zethu zigubungela iprofayili ye-aluminium yeprofayili yesixhobo somatshini, izixhobo zokugaya ityhubhu yensimbi engenasici kunye neendawo ezisecaleni, okwangoku sinokubonelela ngenkonzo elungelelanisiweyo kubandakanya iseti epheleleyo yoomatshini abafana neplanti yokugalela, umgca we-ss ityhubhu yokusila, umgca wokushicilela osetyenzisiweyo we-extrusion, umatshini wokupolisha umbhobho wentsimbi kunye njalo njalo, zombini ukugcina ixesha le-clients' kunye nemizamo. 2.Q: Ngaba unikezela ngenkonzo yokufakela kunye noqeqesho ngokunjalo? A: Iyasebenza.Singalungiselela iingcali ukuncedisa ufakelo, uvavanyo kunye nokubonelela ngoqeqesho emva kokufumana iimveliso zethu zezixhobo. 3.Q: Ukuqwalasela oku kuya kuba yintengiso yelizwe, sinokuqiniseka njani ukuba umgangatho wemveliso? A: Ngokusekwe kumgaqo wobulungisa kunye nokuthembela, ukujonga indawo ngaphambi kokuba ukuhanjiswa kuvunyelwe.Unokujonga umatshini ngokuhambelana nemifanekiso kunye neevidiyo esizinikezayo. 4.Q: Ngawaphi amaxwebhu aya kufakwa xa kuhanjiswa iimpahla? A: Amaxwebhu okuthumela ngenqanawa aquka: CI/PL/BL/BC/SC/SC etc okanye accoding to client’s requirements. 5.Q:Ukuqinisekisa njani ukhuseleko lokuthuthwa kwempahla? IMPENDULO: Ukuqinisekisa ukhuseleko lokuthuthwa kwempahla, i-inshurensi iya kuwugubungela umthwalo.Ukuba kukho imfuneko, abantu bethu baya kulandelela kwindawo yokufaka iikhonteyina ukuqinisekisa ukuba indawo encinci ayiphoswanga.