Sisal Mix Cloth Wheel Buffing Wheels Customizable Cotton Polishing Cloth Wheel for Stainless Steel Metal Polishing

Application:

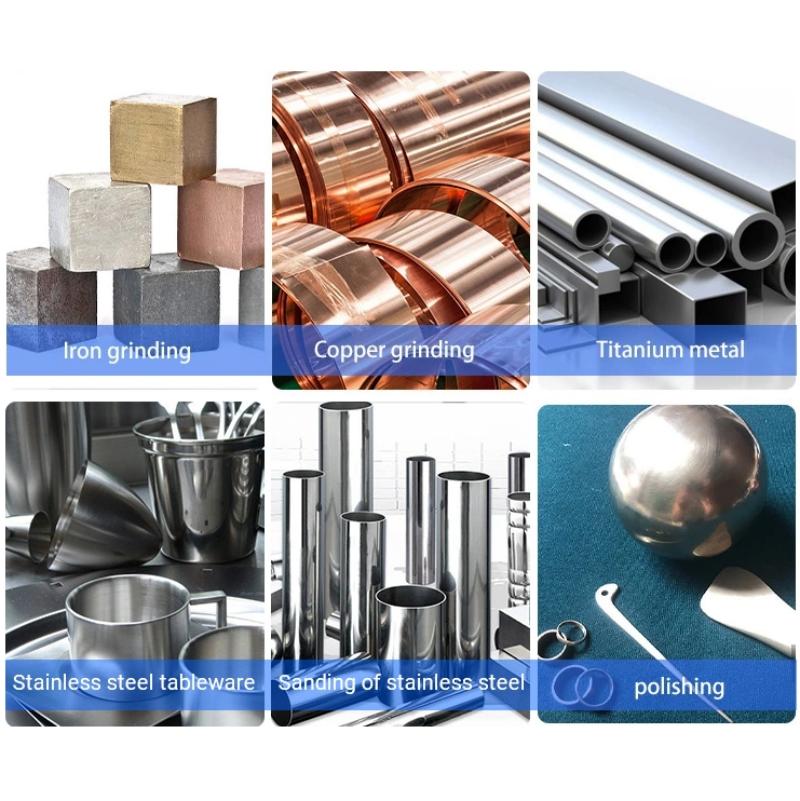

This product is usually used for the final polishing process of grinding, also known as mirror finish. The wind whee/ usually divides poplin and rain cloth two kinds, the difference lies in rain cloth Hardness, density than poplin high, grinding force, wear- resistant

Used for:Same as the polishing after polishing, it is also called mirror treatment. It is suitable for mirror polishing treatment of plastic products (such as ABS plastic, plexiglass, acrylic, etc.), hardware products (stainless steel, aluminum alloy, zinc alloy, iron products, etc.), usually with white wax or green wax.

Product Description:

|

Polishing cloth wheel, which is made of cloth wheel and using for polishing It is one of the commonly used materials for polishing machine

|

||||

|

Performance:

|

This kind of product is usually cut at a 45 degree Angle with fine cotton, and then processed /t has good softness and slight grinding force

|

|||

|

Purpose:

|

This product is usually used for the final polishing process of grinding, also known as mirror finish. The wind whee/ usually divides poplin and rain cloth two kinds, the difference lies in rain cloth Hardness, density than poplin high, grinding force, wear- resistant

|

|||

|

Features:

|

the gap between each page is large and wavy, the air in the wind pi has a cooling effect during polishing, will not burn the workpiece

|

|||

| Outside diameter: 300mm-350mm-400mm |

| Inisde Hole: 25mm/36mm/38mm or customized |

| Thickness:12mm or customized |

Feature:

1.Abrasive and cloth substrate keep synchronous consumption

2.Good heat dissipation, do not burn black work pieces

3.Good brightness after grinding, can be used as one-time grinding

4.No need last procedure of polishing

1.Q:What are your major products?

A:Our products cover aluminium profile mechanical equipment, stainless steel tube mill equipment & spare parts, meanwhile we can provide customized service including a complete set of machines like casting plant, ss tube mill line, used extrusion press line, steel pipe polishing machine and so on, both saving clients’time and efforts.

2.Q:Do you provide installation and training service as well?

A:It is workable. We can arrange specialists to assist installation, testing and provide training after you receive our equipment products.

3.Q:Considering this will be a cross-country trade,how can we make sure the product quality?

A:Based on the principle of fairness and trust, site checking before delivery is allowed. You can check the machine through according to the pictures and videos we provide.

4.Q:What documents will be included when delivering the goods?

A:Shipping documents including : CI/PL/BL/BC/SC etc or accoding to client's requirement.

5.Q:How to guarantee the cargo transportation safety?

A:To guarantee the cargo transportation safety, insurance will covers the cargo. If necessary, our people would follow up at the container stuffing location to make sure a tiny part is not missed.