Regenerative Aluminium Melting Furnace for Billet Casting Aluminium Smelting Furnace

Application:

Fixed melting and holding furnace mainly used in smelting of aluminum alloy or heat preservation for molten aluminum as it has good sealing property.

Product Description:

Technical Parameters

Capacity: 5-60t

Fuel Type: Natural Gas, LPG, Heavy oil, Diesel

Furnace Type: Hydraulic Cylinder Tilting / Stationary

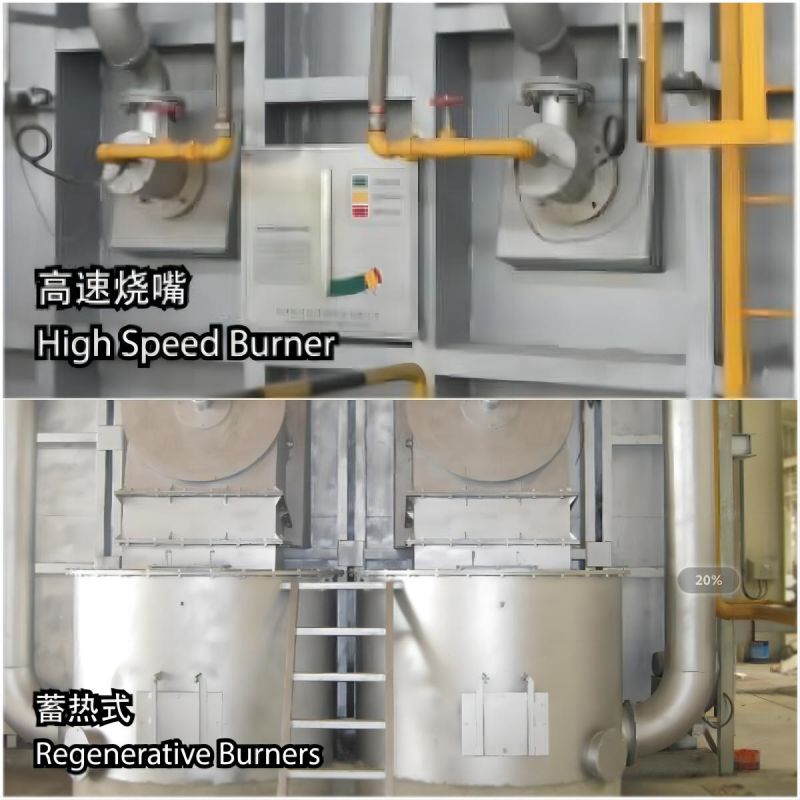

Burner Type: Regenerative/High Speed

Application: Aluminium Molten Metal Melting 1 Holding

Melting Rate: 2-8t.al/per hour

Through careful design of the shell with perfect structure, reasonable application of refractory materials and mechanical equipment, combined with the experience and technology of aluminum smelting equipment accumulated by the aluminum equipment factory for many years, the equipment is highly advanced: the best smelting products, the lowest fuel consumption, and the significant reduction of labor intensity and maintenance workload of workers.

Product Specification:

1.Production: 5 tons- 60 tons

2.Furnace door type: Inclined furnace door

3.Melting rate: 2-8 tons of aluminum per hour

4.Air pressure: 65-100kPa

5.Temperature accuracy: ±5℃

6.Fuel consumption: 52meter cube/ tons*aluminum

7.Highest working temperature: 1050℃

8.Highest control temperature: 1100℃

Feature:

1.Smaller energy consumption, lowest fuel consumption reaches 52meter cube/ tons*aluminum (Calculated based on natural gas)

2.Implement regenerative burner system, low temperature of the waste gas which is about 250℃ and hence reducing the heat carried away from the furnace. Energy lost is minimized.

3.It controls the temperature with thermocouple discontinuous temperature measurement. Fire power is adjusted automatically which achieve the purpose of energy saving.

4.It is shut tightly by the weight of the furnace door, simple structure, easy maintenance.

Burner Type Selection

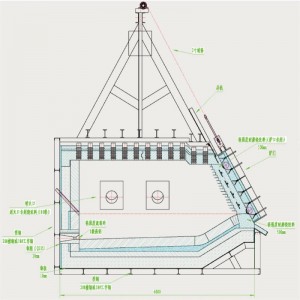

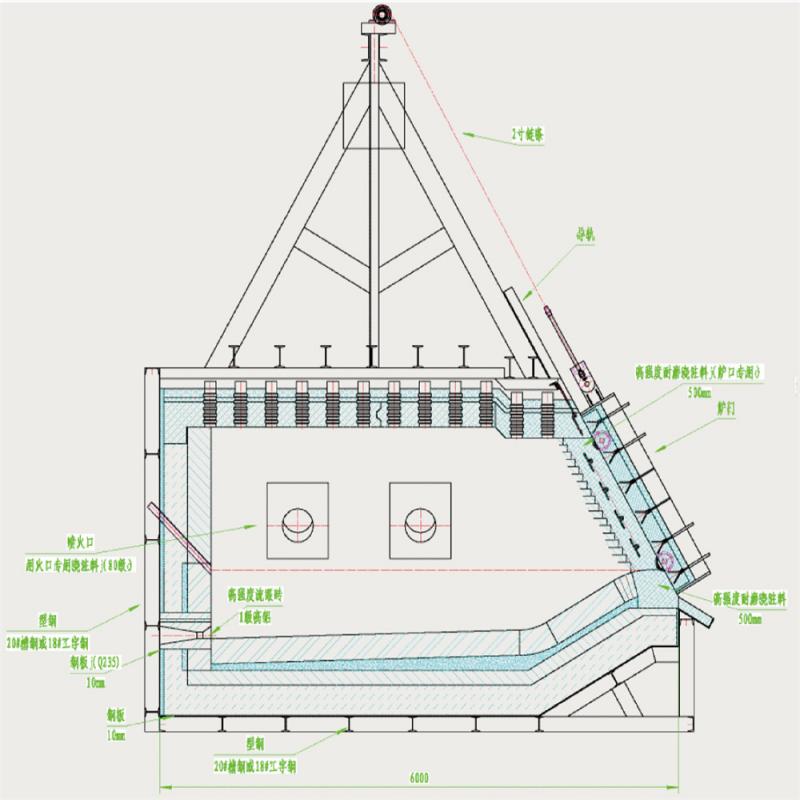

Melting Furnace Lining Selection

1.Q:What are your major products?

A:Our products cover aluminium profile mechanical equipment, stainless steel tube mill equipment & spare parts, meanwhile we can provide customized service including a complete set of machines like casting plant, ss tube mill line, used extrusion press line, steel pipe polishing machine and so on, both saving clients’time and efforts.

2.Q:Do you provide installation and training service as well?

A:It is workable. We can arrange specialists to assist installation, testing and provide training after you receive our equipment products.

3.Q:Considering this will be a cross-country trade,how can we make sure the product quality?

A:Based on the principle of fairness and trust, site checking before delivery is allowed. You can check the machine through according to the pictures and videos we provide.

4.Q:What documents will be included when delivering the goods?

A:Shipping documents including : CI/PL/BL/BC/SC etc or accoding to client's requirement.

5.Q:How to guarantee the cargo transportation safety?

A:To guarantee the cargo transportation safety, insurance will covers the cargo. If necessary, our people would follow up at the container stuffing location to make sure a tiny part is not missed.