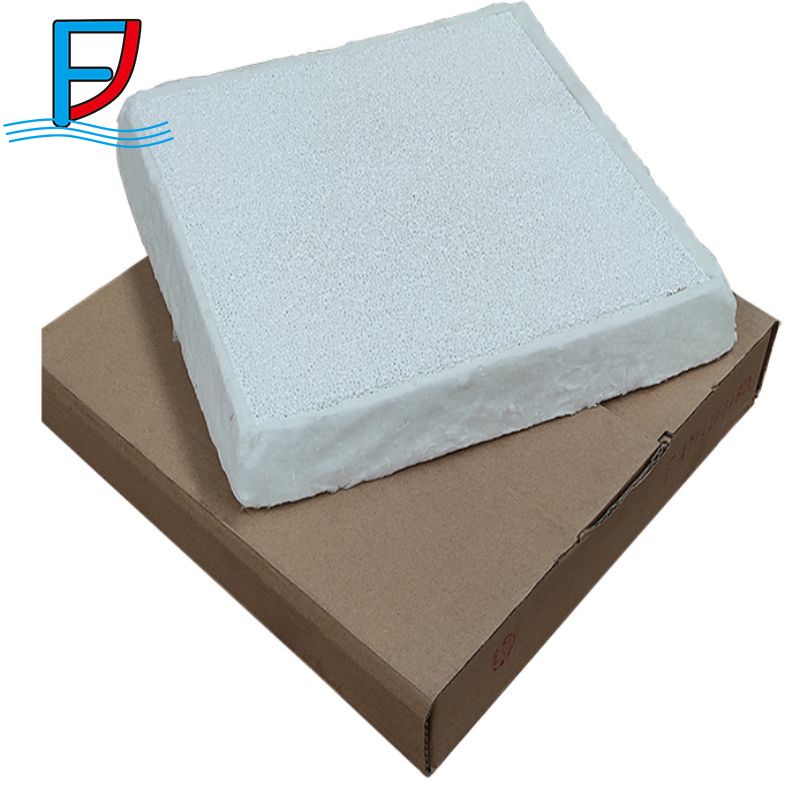

Ceramic Foam Filter Thermal Insulation for Aluminium Billet Casting Plant

Application:

Alumina foam ceramic filter is widely used in aluminum alloy casting rods, flat ingot, aluminum foil, aluminum cans and high-end aluminum profiles and other aluminum casting workshops. The filtration rate of impurity particles of 15 to 20 microns is 98.3%, which can help obtain perfect aluminum products. According to customer requirements, we can produce a variety of specifications, from 10ppi to 40ppi, with a maximum size of 23 inches.

Product Description:

| Main Material | Alumina |

| Temperature | ≤1200 |

| Color | White |

| Cell Density (PPI) | 10-40(PPI=pore per inch) |

| Porosity(%) | 80-90 |

| Compressive Strength at Indoor Temperature (MPa) |

≥1.0 |

| Density (g/cm3) | 0.4-0.5 |

| Thermal Shock Resistance | 6次/800℃-Indoor |

Dimension (± 3 mm

): 7x7in 9x9in 12x12in 15x15in 17x17in 20x20in 23x23in 26x26in

Thickness: 50 ± 2 mm

Bevel Angle: 17.5± 1.5°

Special Dimension: square, rectangular, round, trapezoidal, abnormal, or customized as per the requirement.

Advantage:

- 1.Adopt the adsorption principle for Ceramic Foam Filter, which can effectively remove big piece inclusions in molten aluminum, and effectively adsorb tiny inclusions.

- 2.No broken bits drop out, effectively reducing the pollution of molten aluminum.

- 3.Superior thermal shock resistance improves the erosion resistance ability of molten metal.

- 4.Automatic flow production,3 calibration procedures, precision size, fit the filter housing tightly.

- 5.Improve the surface appearance and performance, and purify molten aluminum.

-

Technical Parameters:

Item Density

(g/cm³)Rupture Modulus

(816℃ /Mpa)Comprehensive Strength

(Mpa)Operating Temperature

(℃)Sealing gasket expanding temperature

(℃)Index 0.45 5.5 0.8-1.0 1350 450-550

Feature:

Instructions for Ceramic Foam Filter

- Inspect and clean the surface of the filter housing, keep it clean and intact.

- Gently lay the filter in the filter housing, and press the sealing gasket around the filter by hand to prevent molten aluminum from dispersing or floating away.

- Use electric or gas burning to preheat the filter housing and ceramic foam filter evenly for 15-30 minutes, making sure their temperature is close to molten aluminum. The preheating temperature for the ceramic foam filter should above 260℃. Expanding cotton will seal after preheating. This procedure makes the ceramic foam filter steadily fixed in molten aluminum. Preheating also leads ceramic foam filter pores to open and avoid occlusion caused by thermal expansion and contraction.

- Observe the change of molten aluminum height, and hold molten aluminum flow in standard needs. Normal starting molten aluminum height is 100-150mm. The height falls down below 75-100mm when molten aluminum flows, and it will slowly increase later.

- Do not hit or shake ceramic foam filter infiltration. At the same time, control the molten aluminum flow rate in the launder, never to be too much or too little.

- Take out the ceramic foam filter and clean the filter housing in time after filtering.

1.Q:What are your major products?

A:Our products cover aluminium profile mechanical equipment, stainless steel tube mill equipment & spare parts, meanwhile we can provide customized service including a complete set of machines like casting plant, ss tube mill line, used extrusion press line, steel pipe polishing machine and so on, both saving clients’time and efforts.

2.Q:Do you provide installation and training service as well?

A:It is workable. We can arrange specialists to assist installation, testing and provide training after you receive our equipment products.

3.Q:Considering this will be a cross-country trade,how can we make sure the product quality?

A:Based on the principle of fairness and trust, site checking before delivery is allowed. You can check the machine through according to the pictures and videos we provide.

4.Q:What documents will be included when delivering the goods?

A:Shipping documents including : CI/PL/BL/BC/SC etc or accoding to client's requirement.

5.Q:How to guarantee the cargo transportation safety?

A:To guarantee the cargo transportation safety, insurance will covers the cargo. If necessary, our people would follow up at the container stuffing location to make sure a tiny part is not missed.