1.5m CNC Lathe Precision Automatic CNC drilling and milling machine

Application:

The equipment is used in minimalist wardrobe material processing, milling handle processing, deep processing, aluminum processing, aluminum doors and Windows and other aluminum processing

Product Description:

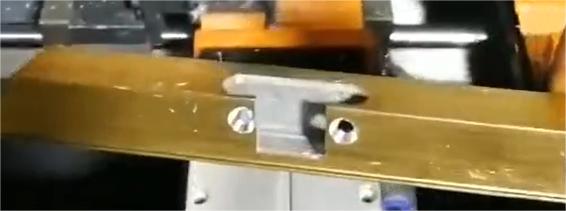

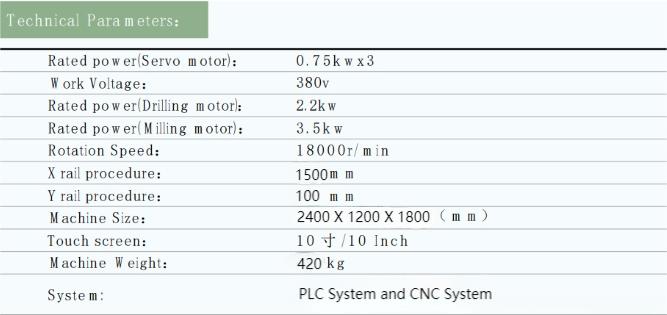

The 3-axis double-head CNC drilling and milling machine has a stroke of 15 meters; Product configuration using servo motor joint bay precision linear guide rail, silk paper, domestic brand high-speed spindle motor configuration.

The system adopts imported Taiwan/domestic high-end system, so that the equipment performance is more stable, the data is more accurate. We continue to upgrade to become more simple, easy to learn, powerful, and more widely used.

This equipment used in minimalist wardrobe material processing, milling handle processing, deep processing, aluminum processing, doors and Windows aluminum profiles and other aluminum processing.

1.Q:What are your major products?

A:Our products cover aluminium profile mechanical equipment, stainless steel tube mill equipment & spare parts, meanwhile we can provide customized service including a complete set of machines like casting plant, ss tube mill line, used extrusion press line, steel pipe polishing machine and so on, both saving clients’time and efforts.

2.Q:Do you provide installation and training service as well?

A:It is workable. We can arrange specialists to assist installation, testing and provide training after you receive our equipment products.

3.Q:Considering this will be a cross-country trade,how can we make sure the product quality?

A:Based on the principle of fairness and trust, site checking before delivery is allowed. You can check the machine through according to the pictures and videos we provide.

4.Q:What documents will be included when delivering the goods?

A:Shipping documents including : CI/PL/BL/BC/SC etc or accoding to client's requirement.

5.Q:How to guarantee the cargo transportation safety?

A:To guarantee the cargo transportation safety, insurance will covers the cargo. If necessary, our people would follow up at the container stuffing location to make sure a tiny part is not missed.