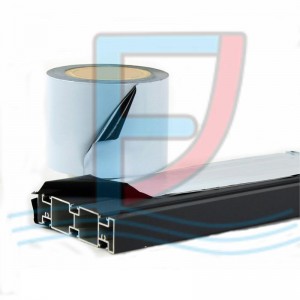

Aluminium profile packing machine aluminium extrusion packing equipment

Application:

1. Aluminum/Steel Plastic composite panel;

2.Aluminum Honeycomb core composite panel;

3. Aluminum Wood Composite Panel;

4. Metal Composite Panel;

5. House Decoration Composite Panel.

Product Description:

l Aluminium profile packing machine main function:

The machine is used for packing the finished aluminum extrusion profiles,through this way the surface of the aluminum extrusions can be well protected for transport and store.

l Aluminium profile packing machine working principle:

The big turntable and PVC film drove by the main motor move like a circle .The aluminum extrusion, passed through from feeding motor and turbine gearbox to glue wheel ,makes rectilinear motion while transporting through the center of the big turntable .Thus the film enlace around the aluminum extrusion profiles .

l Aluminium profile packing machine operating steps :

1 Check the lubricationoil level of feeding motor and every part of the machine .

2 Check the conveyer belt to make sure it is tense.

3 Make sure that the direction of the motor is the same as the arrow,and the brake on the turntable is useful.

4 When install the roll film,the machine must be stopped and out of power.

5 Before it starts working, adjust the drive wheel. Adjust the space between the film while it’s working.

6 After finishing packing,the machine must be out of power.

7 Alarm:Don’t approach the machine while it’s working,It must be out of power when re-install the roll film.

Feature:

1). The machine is specially used for automatically wrapping stretch film to goods.

2). It can prevent the goods to be loose, has a function of protecting, save packing cost, reduce the labor intensity and improve packing effect.

Technical Parameters

| Power supply | 380V /220 50Hz or customized |

| Main motor power | 1.5kw |

| Max packing size | 250x250mm(W*H) |

| Profile feeding speed | 4 -20m/min |

| Rotating speed | 97/149rpm |

1.Q:What are your major products?

A:Our products cover aluminium profile mechanical equipment, stainless steel tube mill equipment & spare parts, meanwhile we can provide customized service including a complete set of machines like casting plant, ss tube mill line, used extrusion press line, steel pipe polishing machine and so on, both saving clients’time and efforts.

2.Q:Do you provide installation and training service as well?

A:It is workable. We can arrange specialists to assist installation, testing and provide training after you receive our equipment products.

3.Q:Considering this will be a cross-country trade,how can we make sure the product quality?

A:Based on the principle of fairness and trust, site checking before delivery is allowed. You can check the machine through according to the pictures and videos we provide.

4.Q:What documents will be included when delivering the goods?

A:Shipping documents including : CI/PL/BL/BC/SC etc or accoding to client's requirement.

5.Q:How to guarantee the cargo transportation safety?

A:To guarantee the cargo transportation safety, insurance will covers the cargo. If necessary, our people would follow up at the container stuffing location to make sure a tiny part is not missed.